When a large industrial plant suffered two failure events in as many months earlier this year, it became clear that it was time to reevaluate its maintenance practices.

The company employed two 115 kV power lines from the local utility company. In June of this year, one of the two customer-owned 115 kV switches was having problems. Technicians couldn’t safely go near the 115 kV lines, so the utility company had to take them down. Circuit Breaker Sales NE was called in to evaluate the switch. The team was able to restore the use of the 115 kV switch to the facility until a replacement could be installed.

The company employed two 115 kV power lines from the local utility company. In June of this year, one of the two customer-owned 115 kV switches was having problems. Technicians couldn’t safely go near the 115 kV lines, so the utility company had to take them down. Circuit Breaker Sales NE was called in to evaluate the switch. The team was able to restore the use of the 115 kV switch to the facility until a replacement could be installed.

Shortly thereafter an even more dangerous event forced the company to reevaluate its service practices. An issue with a piece of low-voltage switchgear caused an explosion, vaporizing parts and endangering workers. Standards dictate that maintenance be performed on low-voltage equipment every three to five years, but this equipment hadn’t been serviced for many years.

The company devised a plan to perform maintenance and testing on the 480 V substations, including pulling out breakers, adding protection systems, and putting breakers back in service, but the team at CBS NE felt that wasn’t enough to get the equipment in a safe and reliable condition. This gear was older and needed more to get the circuit breakers operating at speeds necessary to clear faults as they were designed.

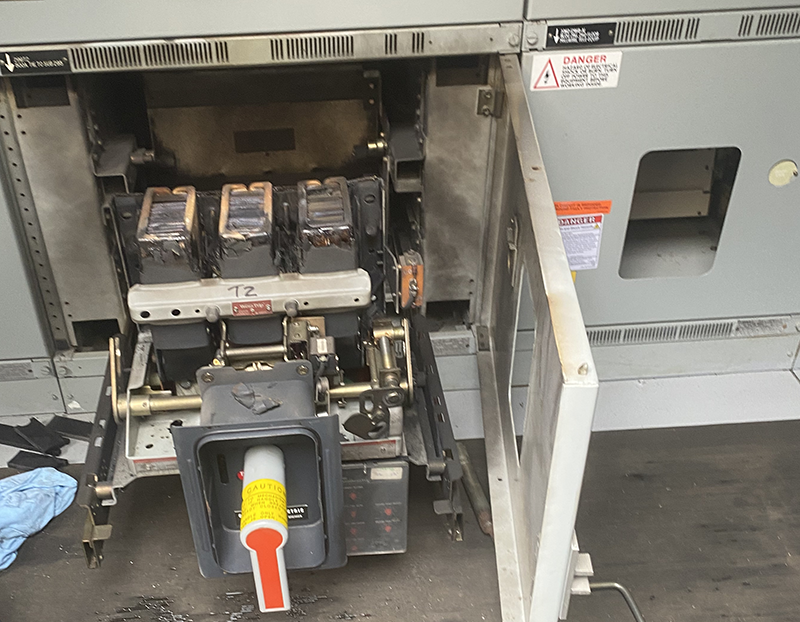

Before the new plan was put in place, the problems escalated further. An arc flash incident in one of the low-voltage substations caused a shutdown of an important part of the facility. Ralph Vito, sales and business development manager at Circuit Breaker Sales NE, got a call to evaluate the damaged substation on a Saturday and was on the scene the next day.

The incident happened on a tie cubicle in the center of the substation, so Vito worked with CBS teams from Boston and Connecticut to disassemble the cubicle and assess the damage. The damaged section was black; the technicians thought it was beyond repair. But the parts team in Seymour, Connecticut, found a way. They tracked down the parts they needed to repair the unit, made new barriers and a copper bus, and cleaned the equipment to put it back in service. It took nearly a week to reenergize the substation, but the six-day outage could have lasted much longer without the quick response and efficient repair provided by CBS NE.

The incident happened on a tie cubicle in the center of the substation, so Vito worked with CBS teams from Boston and Connecticut to disassemble the cubicle and assess the damage. The damaged section was black; the technicians thought it was beyond repair. But the parts team in Seymour, Connecticut, found a way. They tracked down the parts they needed to repair the unit, made new barriers and a copper bus, and cleaned the equipment to put it back in service. It took nearly a week to reenergize the substation, but the six-day outage could have lasted much longer without the quick response and efficient repair provided by CBS NE.

When it came time to contract a partner to take over the facility’s maintenance, CBS NE had already proved its worth and convinced the company to overhaul its original plans. CBS will recondition and upgrade the plant’s metal-clad circuit breakers and work with an on-site service and testing company to maintain the 480 V substations.